The new Air Force IV is a new benchmark in analog sound.

A new benchmark in analog sound. Driven by TechDAS’ innovative ‘air’ technologies, this turntable realizes our vision of ultimate analog reproduction

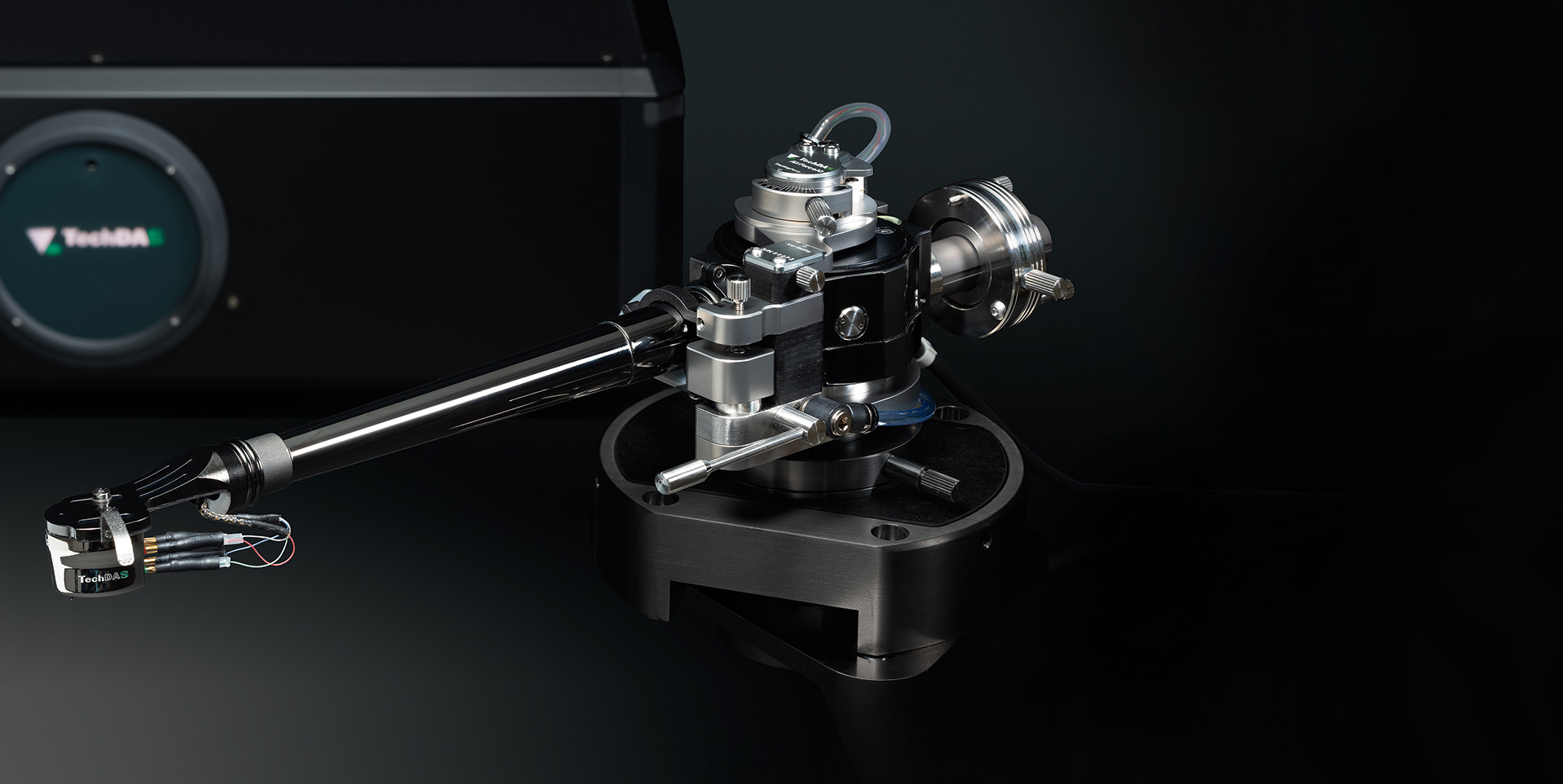

The TechDAS Air Force turntables feature unique pneumatic technologies including air bearing that absolutely isolates the rotating platter and the record from any vibration. Additionally, our vacuum LP hold-down system clamps an LP onto the platter. With these “air” technologies, the Air Force turntables achieve an unparalleled sound quality, compared to conventional analog turntables.

| MAIN UNIT |

| Chassis: One-piece chassis precision machined from solid aluminum alloy A5052. Silver anodized satin finish, 21.5kg |

| Platter: One-piece platter precision machined from solid aluminum alloy A5056, 8.7kg |

| Motor Unit: Precision machined aluminum alloy A5052. Silver anodized satin finish 4.1kg |

| Total moment of inertia: 1.017kg/cm2 |

| Drive system: Belt-drive with double-side polished polyester fabric flat belt |

| Driving motor : External 2-phase 4-pole AC synchronous motor |

| Motor Power Supply : Digital rotational control system driven by power amplifier |

| Rotational speed: 33.3rpm, 45 rpm |

| Wow & Flutter: below 0.03% |

| Dimensions: 420.5 (W) x 168 (H) x 368 (D) mm |

| Total weight: 34.4 kg |

| Minimum dimensions for setting up: 521 (W) x 418 (D) mm |

| POWER SUPPLY UNIT |

| Power consumption: 50W |

| Dimensions: 350(W), 160(H), 270 (D) mm, 9kg |

| Minimum dimensions for setting up: 350(W) x 330(D) mm |

| INCLUDED ACCESSORIES |

| 1x Tonearm Base for rear right or front right positions (drilled for specified tonearm) |

| 1x Platter Cover |

| OPTIONAL ITEMS |

| Extra Tonearm Base (drilled for specified tonearm) |

| – For the rear left position, an exclusive tonearm base is required. |

| – Tonearm bases used on the rear right and front right positions are common with those for Air Force III/ Premium and Air Force V/ Premium |

About TechDAS

TechDAS is the house brand of Stella Inc, the premier distributor of high-end audio in Japan. Stella Inc designs and develops TechDAS products that rediscover the joy of audio and re-activate high-end audio. The brand is working toward the fulfillment of our dream, which is to offer what is truly valuable to users. All products are made in Japan with subtle craftsmanship that elevates the enjoyment of music to an art-form.

“DAS” in TechDAS stands for “Digital Analog Supremacy” reflecting the commitment to the finest audio technology. This philosophy has created TechDAS products such as the Air Force analog turntable line which has gained worldwide reputation for its sound quality, accumulated know-how, and the latest in electronics and precise engineering technology.

“At Stella inc. we imported and distributed many analog audio products, but there was no product that was truly satisfying. Therefore I decided to refine the old Micro Seiki analogue turntables to offer an ideal product. This led us to develop a breakthrough product, the ultimate turntable solution – the TechDAS Air Force One.”